All projects

Ceramic interfaces

Ceramic interfaces

Sensual ceramic interfaces

Sensual ceramic interfaces

Author(s)

Charlotte von Ravenstein

Weißensee kunsthochschule Berlin

,

2024

Build it yourself

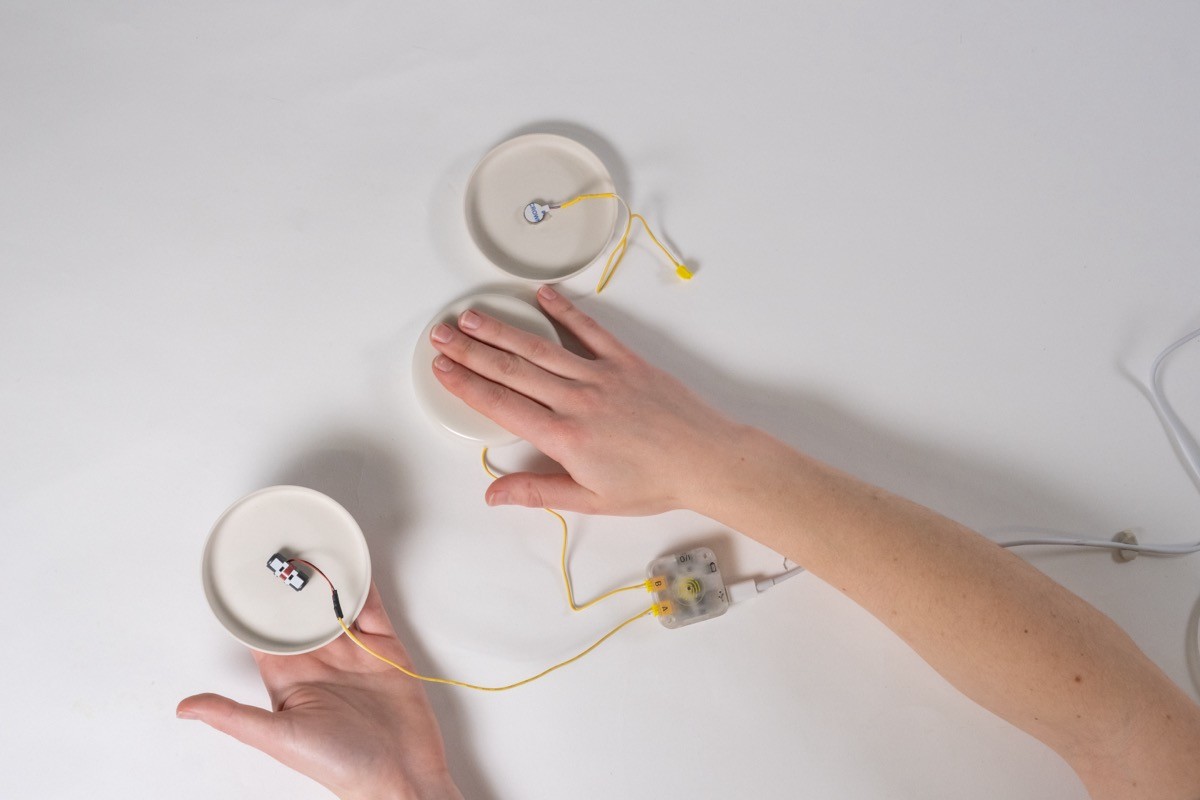

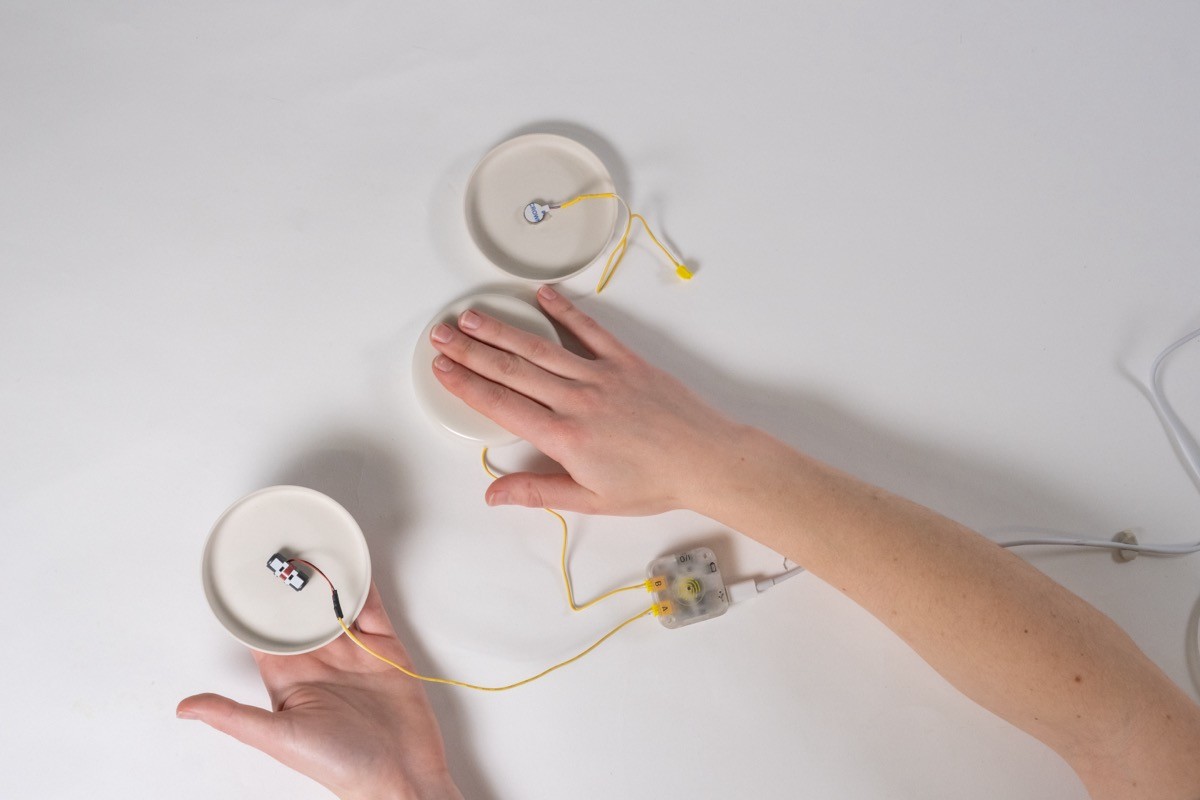

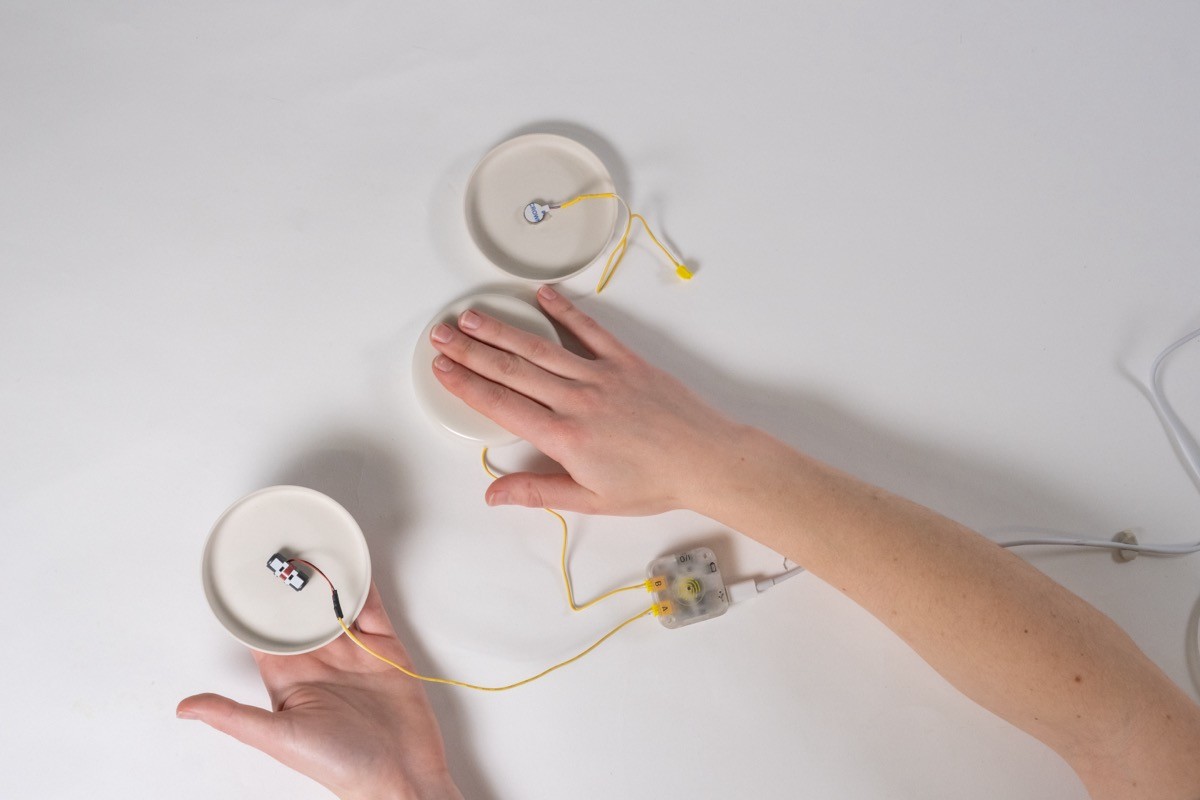

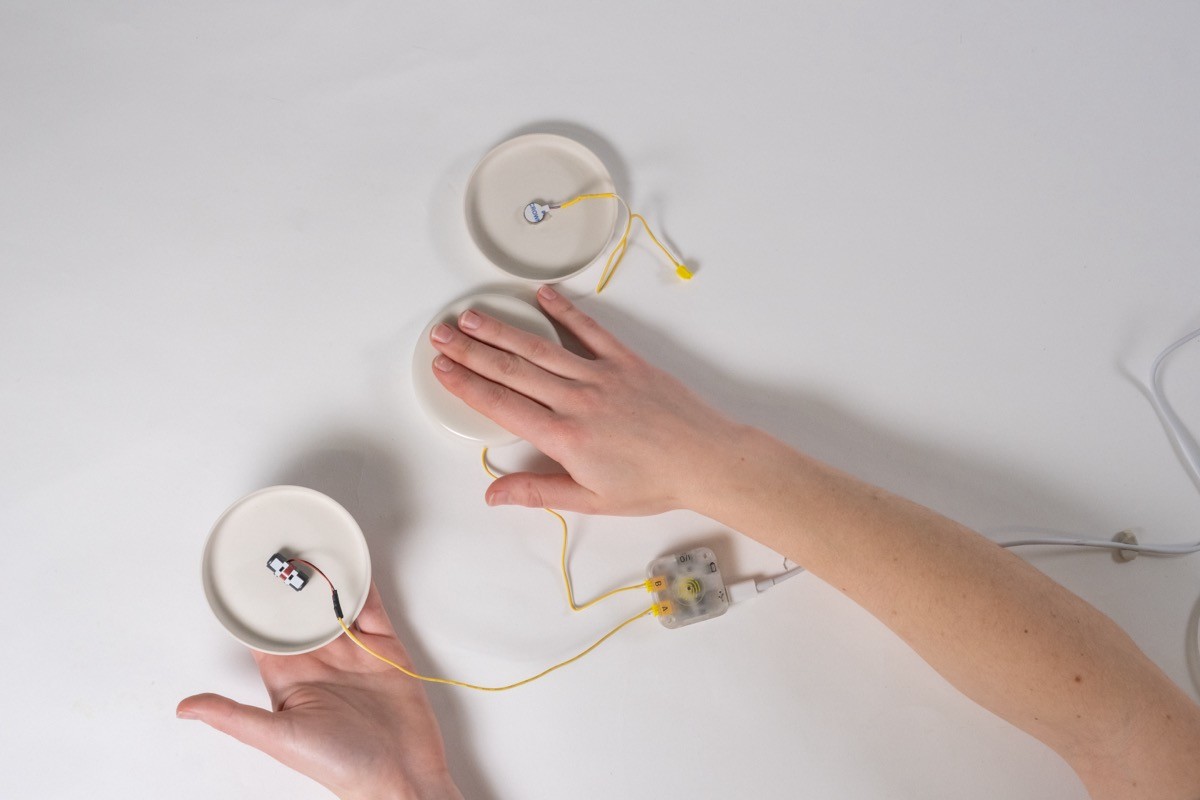

Arduino-nano Hapticlabs Satellite Adafruit-mpr21 Capacitive sensors

Arduino-nano Hapticlabs Satellite Adafruit-mpr21 Capacitive sensors

Arduino-nano Hapticlabs Satellite Adafruit-mpr21 Capacitive sensors

Introduction

Electronic devices are usually made of a combination of plastic and metal and do not last very long. Ceramic has interesting properties: it is extremely durable and simply very beautiful. This project explores the possibilities of designing electronic devices out of ceramics. A special focus is put on the interface and the sensual interaction with the device.

Problem

As a cheap and very short-lived material, plastic in particular has come to epitomise the throwaway culture, which is particularly pronounced in connection with electrical appliances, as they are often outdated and replaced - much to the detriment of our environment and its resources.

Solution

When we start to consider the longevity of electrical appliances, a change of material makes sense. Ceramics have interesting properties: depending on the material composition, they can be extremely stable, resistant to thermal shock or even electrically conductive. At the same time, the visual, tonal and haptic properties of ceramics offer a great deal of creative freedom, giving appliances a different material value. Which makes them a promising alternative Material for designing electronic devices.

Process

Concept and Inspiration: To determine how to translate different interfaces into the new material, inspiration was taken from the way many smartphones provide haptic feedback, mimicking the feeling of pressing a mechanical button when interacting with a touch screen.

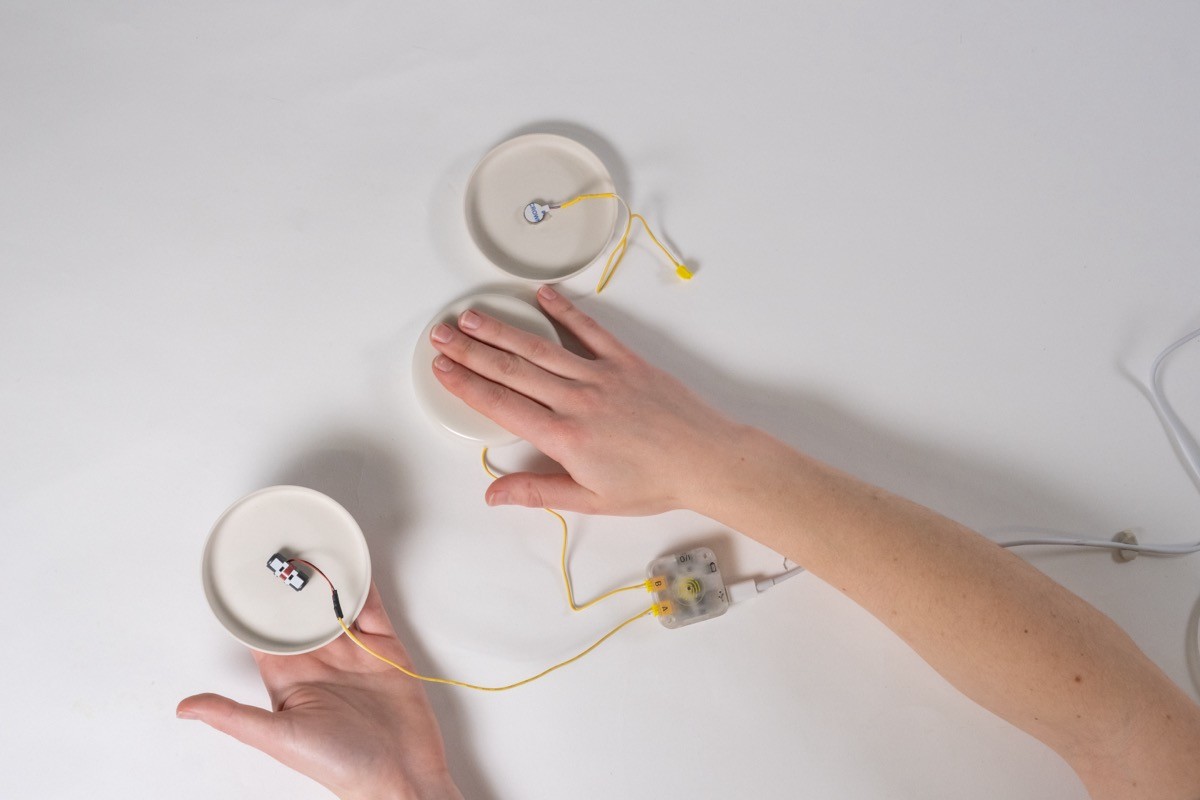

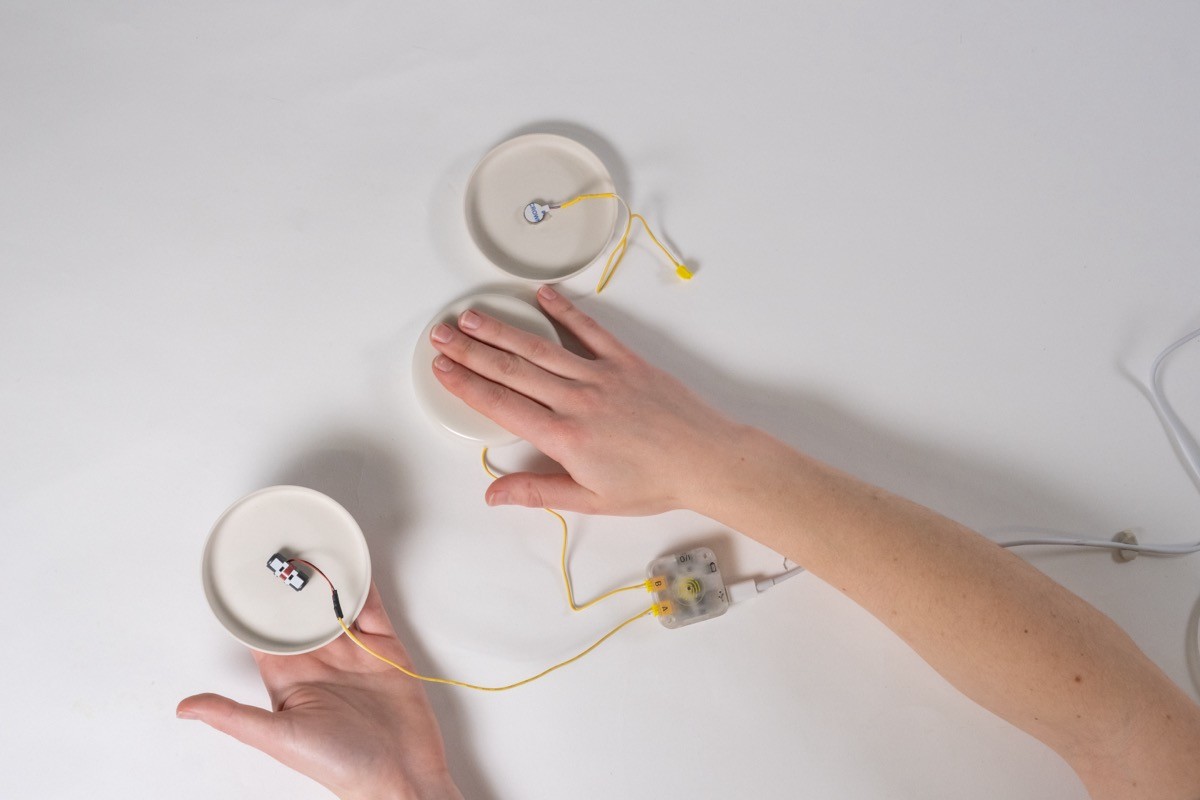

Design and Development: In a series of experiments, the interplay of wall thickness, different impulse intensities, and surface finishes was systematically tested to create the most appealing sensory interaction. The prototypes are shaped like flat cylinders with rounded edges. Their elevated form allows for easy reach of the buttons without looking at them and enables a variety of gestures to be tested.

Technical Implementation: Self-built capacitive sensors were used along with various actuators from the kit. The capacitive sensors were designed to enable different actions such as swiping and circling.

Haptics

Challenges: During the process, the challenge was not just to translate existing technologies into ceramics, but to use the opportunity to improve digital interfaces as a whole

Benefits: Touch sensors are more durable and cost-effective than mechanical buttons. When combined with tactile feedback, they are just as intuitive and offer greater flexibility in designing interactions.

Introduction

Electronic devices are usually made of a combination of plastic and metal and do not last very long. Ceramic has interesting properties: it is extremely durable and simply very beautiful. This project explores the possibilities of designing electronic devices out of ceramics. A special focus is put on the interface and the sensual interaction with the device.

Problem

As a cheap and very short-lived material, plastic in particular has come to epitomise the throwaway culture, which is particularly pronounced in connection with electrical appliances, as they are often outdated and replaced - much to the detriment of our environment and its resources.

Solution

When we start to consider the longevity of electrical appliances, a change of material makes sense. Ceramics have interesting properties: depending on the material composition, they can be extremely stable, resistant to thermal shock or even electrically conductive. At the same time, the visual, tonal and haptic properties of ceramics offer a great deal of creative freedom, giving appliances a different material value. Which makes them a promising alternative Material for designing electronic devices.

Process

Concept and Inspiration: To determine how to translate different interfaces into the new material, inspiration was taken from the way many smartphones provide haptic feedback, mimicking the feeling of pressing a mechanical button when interacting with a touch screen.

Design and Development: In a series of experiments, the interplay of wall thickness, different impulse intensities, and surface finishes was systematically tested to create the most appealing sensory interaction. The prototypes are shaped like flat cylinders with rounded edges. Their elevated form allows for easy reach of the buttons without looking at them and enables a variety of gestures to be tested.

Technical Implementation: Self-built capacitive sensors were used along with various actuators from the kit. The capacitive sensors were designed to enable different actions such as swiping and circling.

Haptics

Challenges: During the process, the challenge was not just to translate existing technologies into ceramics, but to use the opportunity to improve digital interfaces as a whole

Benefits: Touch sensors are more durable and cost-effective than mechanical buttons. When combined with tactile feedback, they are just as intuitive and offer greater flexibility in designing interactions.

Introduction

Electronic devices are usually made of a combination of plastic and metal and do not last very long. Ceramic has interesting properties: it is extremely durable and simply very beautiful. This project explores the possibilities of designing electronic devices out of ceramics. A special focus is put on the interface and the sensual interaction with the device.

Problem

As a cheap and very short-lived material, plastic in particular has come to epitomise the throwaway culture, which is particularly pronounced in connection with electrical appliances, as they are often outdated and replaced - much to the detriment of our environment and its resources.

Solution

When we start to consider the longevity of electrical appliances, a change of material makes sense. Ceramics have interesting properties: depending on the material composition, they can be extremely stable, resistant to thermal shock or even electrically conductive. At the same time, the visual, tonal and haptic properties of ceramics offer a great deal of creative freedom, giving appliances a different material value. Which makes them a promising alternative Material for designing electronic devices.

Process

Concept and Inspiration: To determine how to translate different interfaces into the new material, inspiration was taken from the way many smartphones provide haptic feedback, mimicking the feeling of pressing a mechanical button when interacting with a touch screen.

Design and Development: In a series of experiments, the interplay of wall thickness, different impulse intensities, and surface finishes was systematically tested to create the most appealing sensory interaction. The prototypes are shaped like flat cylinders with rounded edges. Their elevated form allows for easy reach of the buttons without looking at them and enables a variety of gestures to be tested.

Technical Implementation: Self-built capacitive sensors were used along with various actuators from the kit. The capacitive sensors were designed to enable different actions such as swiping and circling.

Haptics

Challenges: During the process, the challenge was not just to translate existing technologies into ceramics, but to use the opportunity to improve digital interfaces as a whole

Benefits: Touch sensors are more durable and cost-effective than mechanical buttons. When combined with tactile feedback, they are just as intuitive and offer greater flexibility in designing interactions.

Stay in the loop

Join our mailing list for occasional newsletters and the latest updates.

Stay in the loop

Join our mailing list for occasional newsletters and the latest updates.

Stay in the loop

Join our mailing list for occasional newsletters and the latest updates.